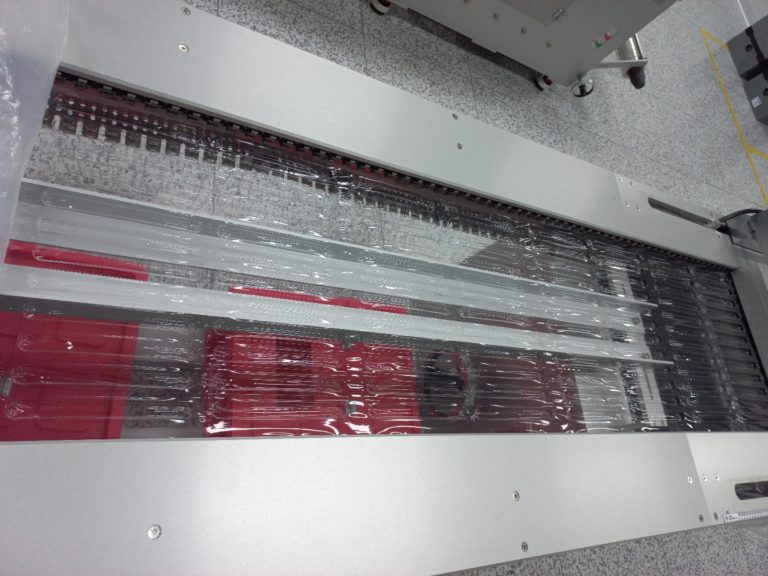

PMW products are safely packaged in GMP facilities and clean rooms through a blister packing process using special film and sterile paper.

The medical device is packaged in a clean room, and the blister packaging method can be used not only for medical swaps, but also for blister packaging and outsourced packaging of various medical devices.

Blister packaging is a process of heating and molding plastic sheets or film papers to create a recessed space. It is a packaging method in which the product is put in the space and covered with paper or plastic film to adhere to the surroundings. PMW’s blister packaging method consists of 3 steps. Heat the special film to form a mold, and then put the product in and adhere the sterilized paper with heat. PMW has three blister packing machines, and the blister packaging process is safely carried out in GMP and clean room facilities.

Heat the special film paper and suck air to make a space for the product.

Infuse air to create a space for the product.

Attach sterilized paper on the film by heating.

Examine the product after blister package.